The debate!

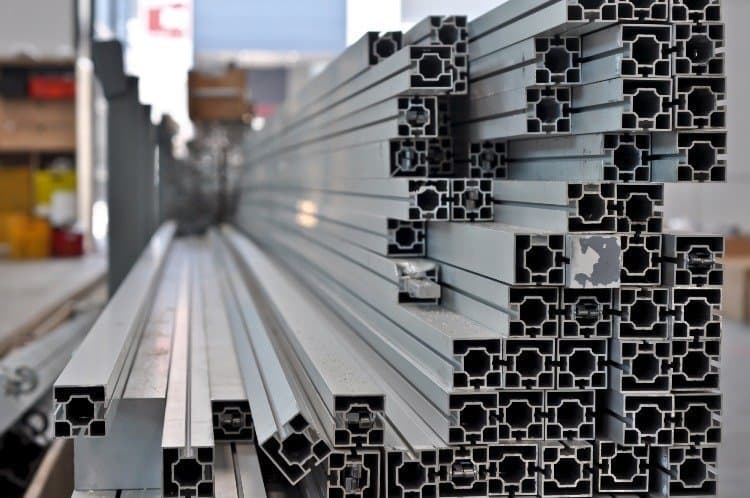

Aluminium is growing in popularity, primarily because of the many, many benefits it offers but also due to advances in technology and the advanced processes of aluminium fabrication. Today so much more can be manufactured from aluminium than even just 20 years ago.

In some people’s eyes aluminium will soon hold the same value, if not outweigh, the value of gold, making it incredibly lucrative and the go-to metal for now.

Expanding its reach across industries and companies as well as providing aid in the development of innovative products, there is no other metal currently out there that offers such extraordinary features.

However, when it comes to looking for comparisons, steel is most likely the only metal that aluminium could be compared too, but in this post, we want to highlight why aluminium should be the clear choice once and for all.

Why aluminium is better

Aluminium is strong, and we mean really strong. It can handle a considerable amount of weight without compromising on the size of frames or casings, which is not possible with other metals, who would have to increase the density of their casement for example in order to take the additional weight.

Aluminium is also known to be much more durable than steel, making it a popular choice for those looking for long-lasting and hard-wearing products (ideal for things like windows and doors, for example).

Due to it lasting longer it also provides cost benefits in the long run too. In the short-term, it is competitively priced with other metals available but lasting longer than other metals means you can save in the future too.

As we’ve mentioned aluminium is used in a variety of different industry sectors, and this is only increasing as other sectors are beginning to see the benefits this material has to offer. Due to its high elasticity and its ability to be shaped and moulded (without breaking) to any specified requirement, is what makes it truly stand out against steel.

Aluminium is also rust-free and resistant from corrosion, not something a product made out of steel can state! Being able to withstand any extreme and harsh conditions that are thrown at it (even saltwater), aluminium is most certainly versatile. This is one of the major reasons that you will find aluminium being used in heavy industries instead of steel, which often needs some sort of treatment (paint or coating) to make it rust-free.

A strong metal doesn’t always mean heavy to handle, and aluminium proves this with its unique lightweight features. Making it easy to transport, you will find aluminium is a crucial element for aircraft, heavy vehicles, and ships, etc.

Again, comparing this to steel, steel is a heavy metal making it somewhat cumbersome to move and transport around. Unfortunately, steel in this sense is only used when there is no other option to choose from!

Aluminium also thinks about the environment. Being 100% recyclable and also consuming less energy during the fabrication process, makes it easy for manufacturers to keep track of their production costs and be more competitive on costs where they need to be.

Unlike steel aluminium is a great conductor of electricity and heat, hence the reason it is used in everyday household appliances. Appliances and applications such as washing machines, condensers, air conditioning units and so much more.

If you work in a sector which involves cutting and moulding metals to fit exact specifications, then aluminium should be your number one choice. Soft and mild (something steel is not) aluminium is extremely feasible.

Aluminium is in high demand for good reason – and we’ve mentioned some of these above! If you’re thinking about inventing a new electronic device, or you’re looking for an alternative to steel, call Crucial Engineering today to find out more about what aluminium fabrication is and how you can maximise its benefits to suit your requirements.